Pulp and Paper Construction

Integrated Solutions from Master Planning to Production and Maintenance

Transforming pulp and paper construction with early engagement and collaboration

In an industry where margins continue to be paper thin, players in the pulp and paper market cannot afford to be inefficient. The stakes are higher than ever for cost and schedule certainty. Speed to market and production efficiencies are of the utmost importance. As the demand for new products surges, the need for additional construction and maintenance work increases. Competitors in this market must partner with innovators who bring proven expertise and cutting-edge solutions to propel projects forward with speed and precision. The time for change is now.

Pulp and paper construction

For over 65 years, Boldt has partnered with pulp and paper manufacturers to build and innovate together. We bring an innovative spirit and industry-leading expertise to every project. Boldt has excelled in paper, tissue and towel, corrugated products, building products and sanitary paper construction and maintenance projects. Together, we achieve more.

Nine Dragons Paper Holdings – No. 25 Paper Machine

Nine Dragons Paper Holdings – No. 25 Paper Machine

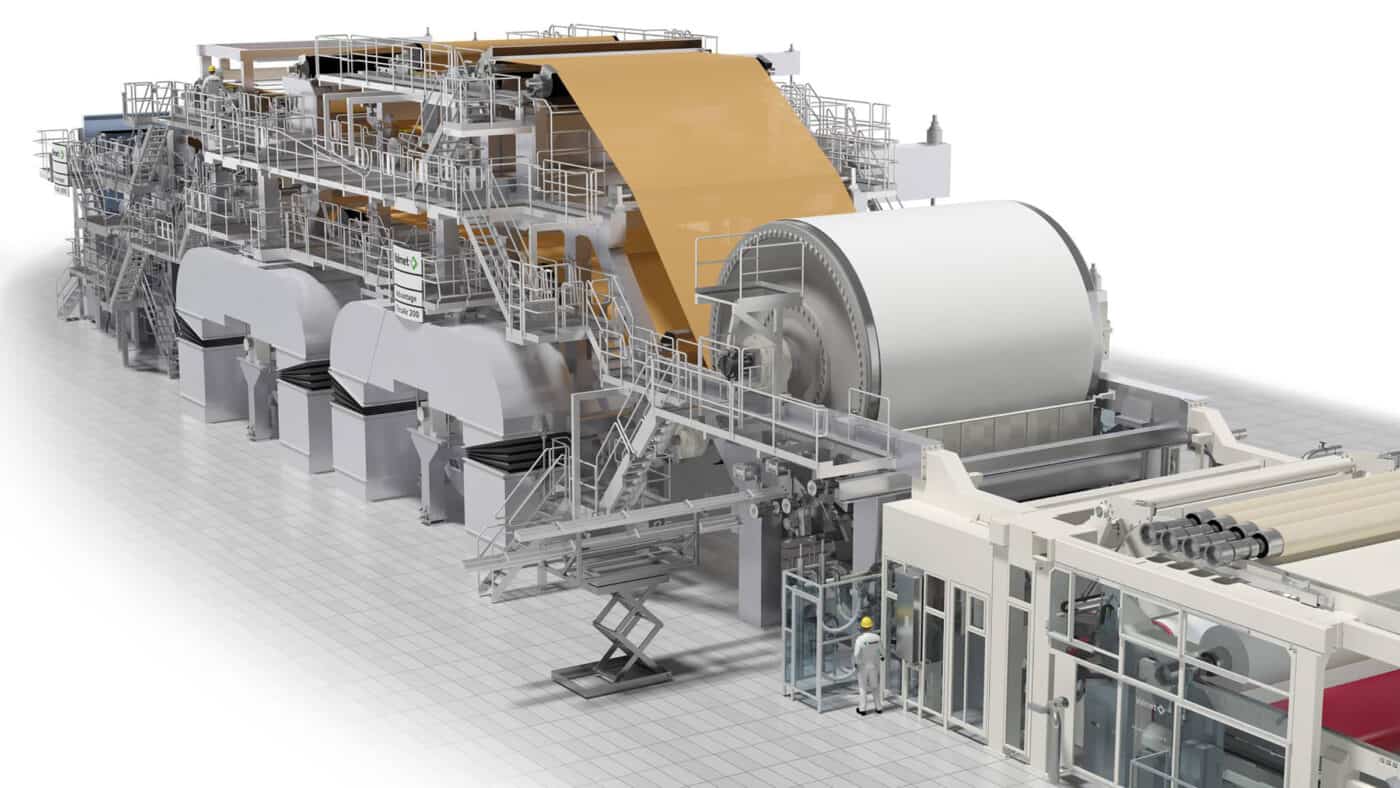

Pulp, paper and tissue machine rebuilds

As equipment reaches its life expectancy and technology evolves, machines require maintenance, repairs, and replacements to operate efficiently or manufacture new products. Boldt brings expertise to meet these needs with integrated project planning and phasing that minimizes downtime. Our skilled teams of millwrights and craft workers perform rebuilds and upgrades, while our engineering and tooling capabilities ensure major lifts and precision installations are completed safely and on schedule.

Technology upgrades are needed to operate more efficiently or manufacture different products. Whatever the need, Boldt brings expertise to deliver. Integrated project planning and phasing that minimizes downtime. Skilled teams of millwrights and craft workers who self-perform. Engineering and tooling to complete major lifts and precision installations. Boldt ensures projects are completed safely and on schedule.

Pulp, paper and tissue machine maintenance

A machine fails. A roller, pump or valve needs replacement. For all the specialized paper machine maintenance service that keeps paper mills running, Boldt crews are equipped to respond when you need them. And, through an exclusive partnership with industry leader OASIS, Boldt crews offer precision alignment methods and tooling to keep you running around the clock.

Coating Excellence International

Coating Excellence International

Converting equipment installation

When pulp and paper manufacturers look for a construction company to install converting equipment, they need someone with the knowledge, experience and skills to perform with precision. Boldt brings decades of experience working with some of the world’s largest OEMs, installing converting equipment that meets exacting specifications, generating higher quality and more efficient production. In the last 10 years alone, we have installed over 25 different converting lines in facilities across the country.

Paper mill construction

As consumer demands shift, pulp and paper manufacturers must be prepared to respond. Whether expansion or new paper mill construction, Boldt brings technical construction services and project planning expertise to navigate the entire project with our trademark Integrated Lean Project Delivery® method, pairing collaboration and problem-solving to drive out waste and drive-up value across the entire project. Please see our latest completed project here : (provide link to Cinco project profile)

Feasibility studies

Undersized or aging facilities. Inefficient manufacturing processes. Changing needs. If bottom lines aren’t budging or growth has stalled, a Boldt feasibility study can help you see what’s possible to meet future needs and move manufacturing forward.

BOLDT BuildS performance specialists

Boldt has been maintaining, building and modernizing pulp and paper facilities for decades. As the industry has changed, so has our approach. Our team of experts are up to date on the latest technologies to ensure your facility upgrades are installed safely, on time.

Pulp and paper: Precision pushes performance

Pulp and paper manufacturers trust Boldt to tackle the most complex pulp and paper construction projects.

Meeting client needs using our proven integrated solutions

Track record of successful projects completed safely and on time

Early engagement at P1 or P2 levels of project planning

Self-perform capabilities to ensure quality and mitigate risk

On-call, emergency paper machine maintenance