Georgia-Pacific – Project Cuatro

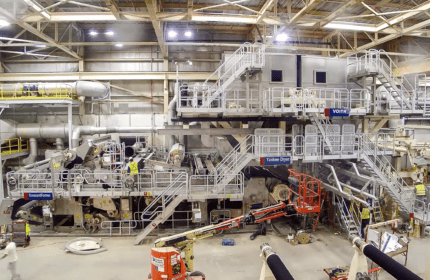

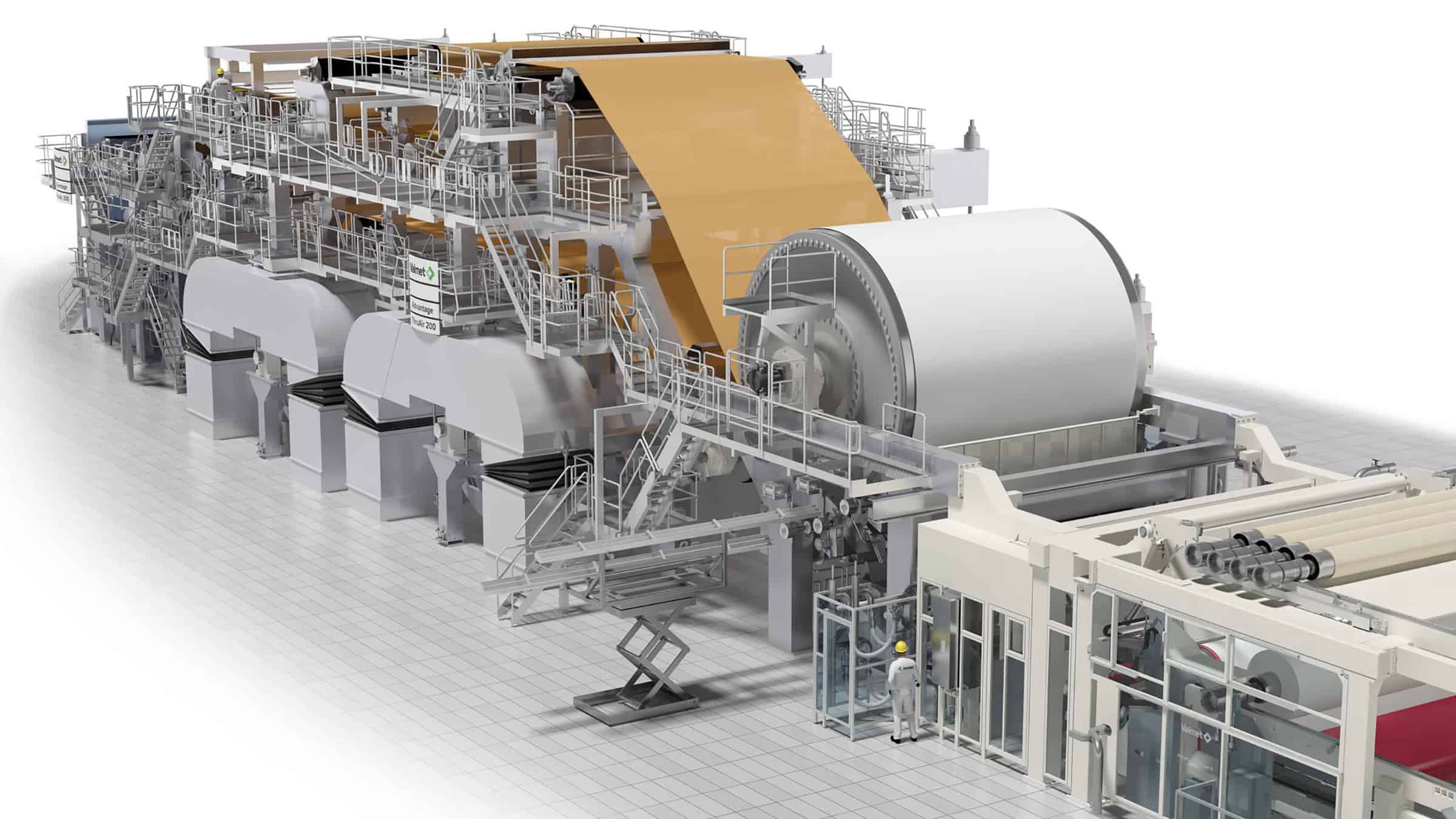

Boldt, Baisch and Georgia-Pacific collaborated early in the development, planning, engineering and construction stages of the project. The broad scope included a new tissue machine installation using through-air-dried (TAD) technology, as well as adding associated converting equipment and infrastructure.

A major accomplishment on the project was the effort to accelerate the machine installation. Boldt, Valmet, Georgia-Pacific and trade partners determined that the most cost-effective solution to shortening the schedule for the machine installation would be to schedule two shifts for the millwright crews to assemble the major portions of the paper machine. This effort opened multiple fronts for piping, electrical, instrumentation and air systems crews to complete their work.

Georgia-Pacific

Palatka, Florida

Baisch Engineering and Foth Production Solutions, LLC

- Construction Manager

- General Contractor

Machine and Converting Equipment Installation and Infrastructure

Project Highlights

- Baisch Engineering and Boldt worked with Georgia-Pacific Engineering on an Integrated Project Delivery (IPD), sharing responsibility and risk for completing the project within budget and schedule.

- Scheduling Millwright crews into two shifts provided a cost-effective and shorter schedule for machine installation, making it easier for others to complete their work.